5′ 8″ diam., 18 oval spokes, vee inner rim, 3½″ apparent tread.

Hub 15¾″ face dia., level with the tyre. Pin between at 14″, (at 13″ for LMS locos.)

Source: BR Standard 2-6-4T class 4MT No. 80151 measured direct at Chappel in 1995.

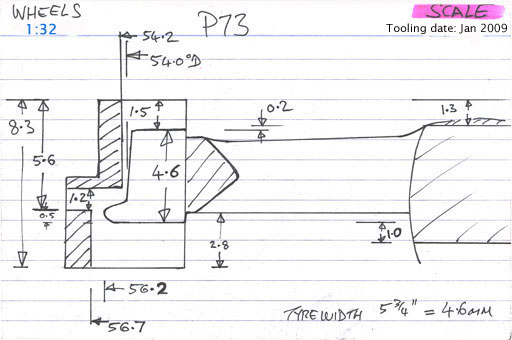

Casting: 54.0 mm tread dia. (54.5 mm for LMS locos), 48.3 mm i/d., hub level with tyre.

Casting prices and stock . BR loco sets, price list

Scan of a casting in a set for a BR 4-6-0 4MT . 2-6-4T 4MT .

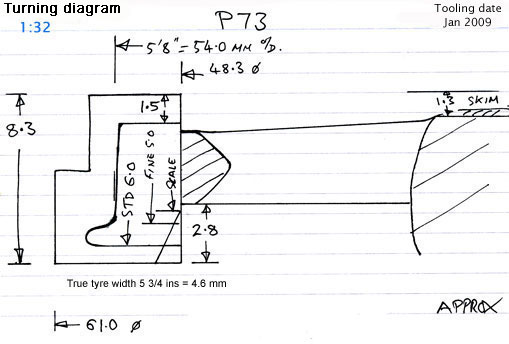

1. mount the casting with its back out and cut the small step on the back.

2. with the front out,

cut the larger step,

face the hub so you leave the whole top face just planed over.

(cut a little high, then another 1 or 2 cuts of 0.01 mm until it looks right).

face the tyre 0.2 mm below the hub.

bore the centre just under the size of the final reamed diameter.

3. with the back out, face the back to 5.0 mm tyre width.

4. mount the casting on a slightly loose (by diameter) mandrel between two discs, centre it, tighten up, and make the final cut with the fine form tool.

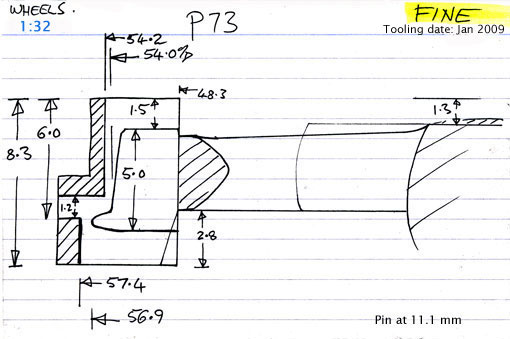

1. mount the casting with its back out and cut the small step on the back.

2. with the front out,

cut the larger step,

face the hub so you leave the whole top face just planed over.

(cut a little high, then another 1 or 2 cuts of 0.01 mm until it looks right).

face the tyre 0.2 mm below the hub.

bore the centre just under the size of the final reamed diameter.

3. with the back out, face the back to 4.6 mm tyre width, for this scale wheel I left an extra 1.0 mm thickness on the back of the hub for

firmer mounting on the insulating bush.

4. mount the casting on a slightly loose (by diameter) mandrel between two discs, centre it, tighten up, and make the final cut with the scale form tool.

27 Mar 2013